Mushonga wekudyisa upfu

1. Nozzle yekudyisa upfu hwecoaxial ine nzira nhatu/nzira ina: upfu hunobuda zvakananga kubva munzira nhatu/nzira ina, hwakabatana pane imwe nzvimbo, nzvimbo yekubatana idiki, nzira yeupfu hainyanyi kukanganiswa negiravhiti, uye divi rayo rakanaka, rakakodzera kudzoreredzwa kwelaser ne3D kudhinda.

2. Mushonga wekudyisa upfu hwecoaxial unopinzwa nemagetsi matatu kana mana, uye mushure mekugadziriswa kwemukati memuviri, upfu hunobuda murin'i uye hunobatana. Nzvimbo yekubatanidza yakakura, asi yakafanana, uye yakakodzera kunyunguduka nelaser ine madonhwe makuru. Yakakodzera laser cladding ine kona yekutsvedza mukati me30°.

3. Mushonga wekudyisa hupfu hwepadivi: chimiro chiri nyore, mutengo wakaderera, kuiswa uye kugadziriswa kuri nyore; daro riri pakati pemaburi ehupfu rakareba, uye kugona kudzora hupfu nechiedza kuri nani. Zvisinei, laser beam ne powder input hazvina kuenzana, uye nzira yekuskena yakaganhurirwa, saka haigone kugadzira cladding layer yakafanana kune chero divi, saka haina kukodzera 3D cladding.

4. Muromo wekudyisa hupfu hwakaita sebha: poda inopinzwa kumativi ese, mushure mekugadziriswa kwehomogenization nemodule yekuburitsa hupfu, poda inobuda yakaita sebha, uye inounganidzwa panzvimbo imwe chete kuti igadzire poda ine strip-shaped powder ine 16mm*3mm (inogona kugadziriswa), uye inoenderana. Kusanganiswa kwestrip-shaped spots kunogona kugadzirisa pamusoro pe laser yakakura uye kuvandudza kushanda zvakanaka.

Chinodyisa upfu

Maparamita makuru ekupa hupfu hwebhareni mbiri

Muenzaniso wekudyara upfu: EMP-PF-2-1

Silinda yekudyisa upfu: kudyisa upfu hwesilinda mbiri, PLC yakazvimirira inodzorwa

Maitiro ekudzora: chinja nekukurumidza pakati pekugadzirisa matambudziko uye maitiro ekugadzira

Saizi: 600mmX500mmX1450mm (kureba, upamhi uye kukwirira)

Vhoriyamu: 220VAC, 50HZ;

Simba: ≤1kw

Saizi yehupfu inotumirwa: 20-200μm

Kumhanya kwedhisiki yekudya nehupfu: 0-20 rpm mutemo wekumhanya usina nhanho;

Kurongeka kwekudya kwehupfu: <±2%;

Manyuko egasi anodiwa: Nitrogen/Argon

Zvimwe: Iyo operation interface inogona kugadziriswa zvinoenderana nezvinodiwa

Laser Pyrometer

Kudzora tembiricha yakavharwa, senge laser quenching, cladding uye surface treatment, kunogona kuchengetedza tembiricha yekuoma kwemipendero, maburi kana maburi nemazvo.

Tembiricha yekuyedza inobva pa700℃ kusvika 2500℃.

Kudzora kwetambo yakavharika, kusvika ku10kHz.

Mapakeji esoftware ane simba e

gadziriro yemaitiro, kuratidzira, uye

kuchengetwa kwedata.

Zviteshi zveindasitiri zve l/O zvine 24V digital uye analog 0-10V l/O yemuchina we automation

kubatanidzwa uye kubatana ne laser.

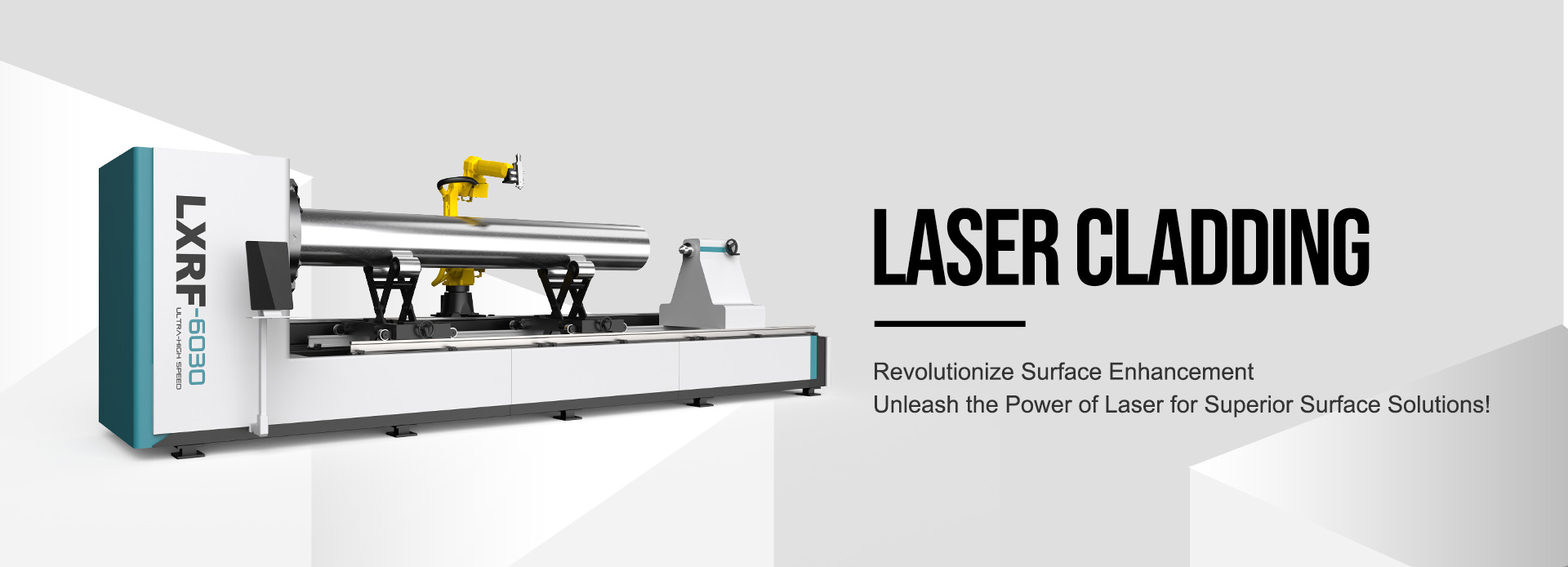

Zvakanakira zveLaser cladding

Zvikumbiro zveLaser Cladding

●Muindasitiri yemotokari, zvakaita semavharuvhu einjini, maburi emasilinda, magiya, zvigaro zvevharuvhu zvinobuda mumhepo nezvimwe zvikamu zvinoda kuramba kupisa zvakanyanya, kuramba kupisa uye kuramba ngura;

●Muindasitiri yezvemuchadenga, mamwe mapoda esimbi anoputirwa pamusoro petitanium alloys kugadzirisa dambudziko retitanium alloys. Zvakaipa zvekukweshana kukuru uye kusapfeka zvakanaka;

●Mushure mekunge pamusoro pechiumbwa muindasitiri yechiumbwa chagadziriswa nelaser cladding, kuoma kwayo pamusoro, kuramba kupfeka, uye kuramba kupisa kwakanyanya zvinovandudzika zvakanyanya;

●Kushandiswa kwelaser cladding pamarongero muindasitiri yesimbi kwave kwakajairika.